PROTOTYPING

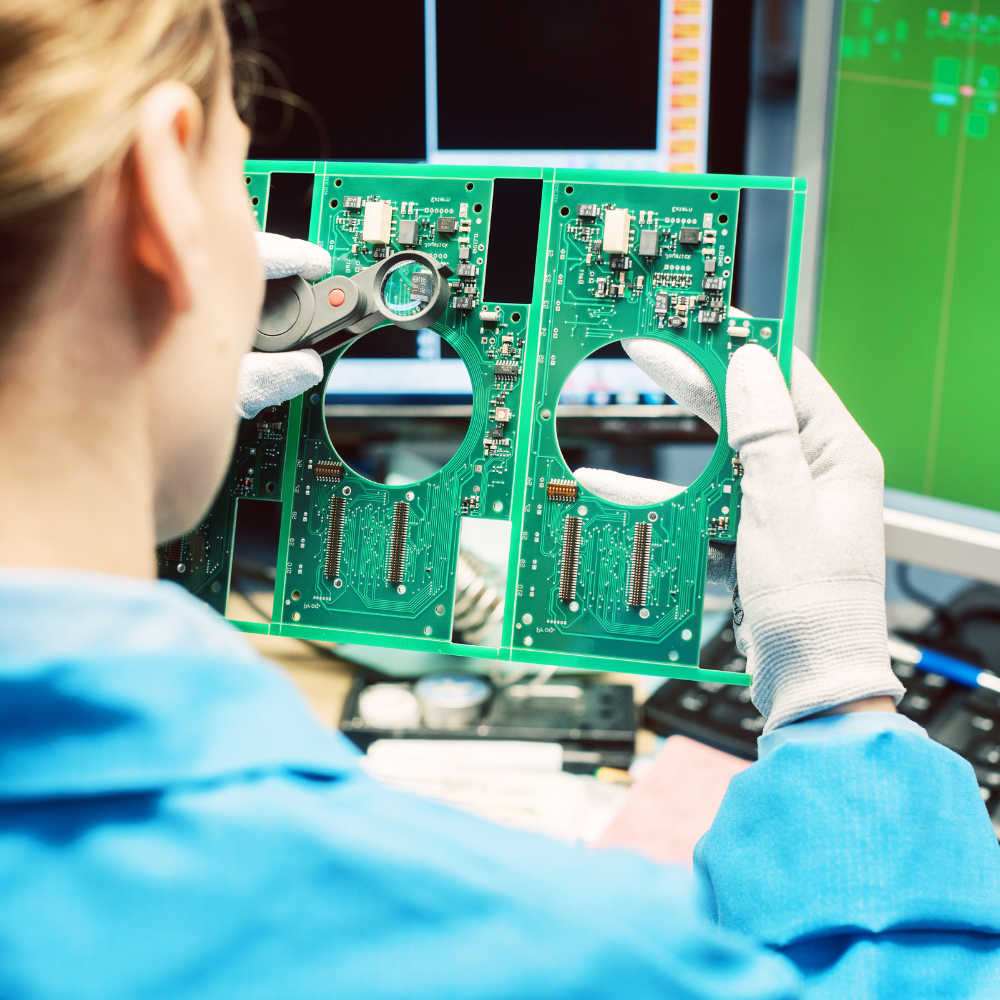

Prototyping is a key stage in the development process of electronic devices, allowing for testing and verification of the design before starting mass production. Prototypes help identify potential errors, optimize functionality, and ensure the final product meets all technical requirements. This process involves creating individual PCB samples that are tested and verified for performance in real-world conditions.

At PROPCB, we understand how crucial time and precision are at this stage, which is why we offer two types of prototyping services tailored to our clients’ needs – Standard Prototypes, optimal for complex projects requiring thorough analysis, and Express Prototypes, perfect for projects needing quick iteration.

Our team supports you at every step, ensuring precise execution and full compliance with the design, so your prototype is ready for further testing and optimization. Regardless of the project scale, we help quickly transition your design from concept to production, accelerating the prototyping process and time-to-market.

HOW TO ORDER PRINTED CIRCUIT BOARDS?

To order printed circuit boards, simply fill out the contact form or email us directly. Our experts will reach out to discuss your project specifications, propose technical solutions, and provide a quotation. We support you at every stage of the collaboration, ensuring a personalized approach and technical support to ensure your PCBs meet your requirements.

LEAD TIMES

We offer various lead times to provide our clients with greater time flexibility, tailored to their needs.

STANDARD PROTOTYPE

Lead time:

10–12 business days

An optimal lead time for prototypes, ensuring favorable time and cost conditions.

SMALL-BATCH PRODUCTION

Lead time:

10–14 business days

Ideal for small to medium series production, ensuring high quality and consistency in longer production cycles.

EXPRESS PROTOTYPE

Lead time:

4–8 business days

Fast PCB prototyping for clients requiring immediate solutions in their design iteration process.

LARGE-SCALE PRODUCTION

Lead time:

14–18 business days

Completion of large orders while maintaining strict quality standards, perfect for mass production and long-term projects.

PCB ORDERING WORKFLOW

Working with PROPCB is transparent and efficient. From the first contact to the delivery of finished PCBs, every stage is carefully planned and monitored.

1

VERIFYING AND APPROVING YOUR PROJECT

Discussing appropriate technologies and materials to meet your requirements.

2

QUOTATION

Fast, accurate, and cost-effective calculation based on project specifications.

3

DESIGN REVIEW

Thorough verification of project files in order to identify errors and potential adjustments.

4

PRODUCTION

Precise manufacturing of printed circuit boards according to the order.

5

TESTING

Rigorous quality and functionality control.

6

DELIVERY

Timely shipment of finished PCBs to the client.

FAQ – FREQUENTLY ASKED QUESTIONS

Do you have questions about our services? Check out the answers to frequently asked questions.

Visit our FAQ section to learn more about the PCB technology details we can apply to your project.

MAKE YOUR PROJECT HAPPEN

Design and bring your project to life with PROPCB. Thanks to our extensive experience and advanced technological capabilities, we deliver solutions that contribute to the success of your project. Contact us today to see how we can help turn your idea into a finished product.