Better management and identification with laser marking of PCBs

At PROPCB, we understand the importance of precise management and tracking of printed circuit boards (PCBs) at every stage of production. Laser marking is a state-of-the-art method that not only supports inventory monitoring, but most importantly, enables accurate tracking of individual batches and even individual PCBs. This is a key advantage in many industries, such as automotive, medical or consumer electronics, where precision and reliability are a priority. Thanks to laser marking, it is possible to quickly detect problem batches and eliminate defective components, which significantly improves the quality of final products.

Various methods of PCB marking

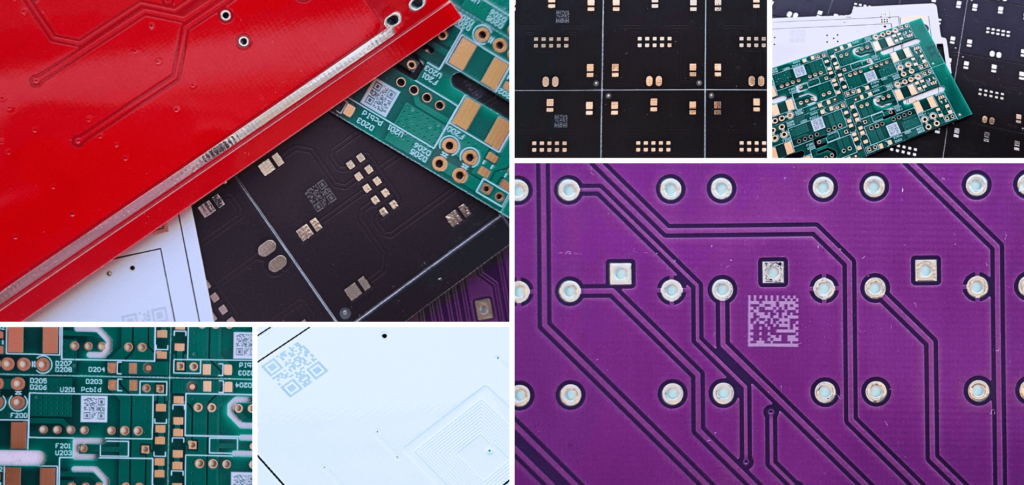

There are several PCB marking methods on the market, each with its own unique characteristics and applications. The simplest method is stickers, but their durability and resistance to external factors is limited. Stickers can peel, rub off or fade over time, making them ineffective for long-term product management.

Laser marking is an advanced method that offers much higher durability and resistance. With this technology, markings are burned directly onto the surface of the PCB, which ensures their resistance to abrasion, moisture and other external factors. Moreover, laser markings such as QR codes or Datamatrix can contain a large amount of information in a small size, which is extremely practical for complex electronic systems.

Why do we choose laser marking?

Laser marking has a number of advantages that make us choose it as the best solution among the available marking methods.

Laser marking offers permanent, legible marking

First and foremost – the laser makes it possible to create permanent, indelible markings, which remain legible throughout the life of the PCB, even in harsh industrial environments. In addition, laser technology eliminates the need for consumables, which translates into lower operating costs and less risk of environmental contamination.

QR codes, Datamatrix and others – maximizing available space to include valuable information

Our laser marking solution also offers precision that other methods cannot. With the ability to burn intricate patterns into small areas, such as QR codes or DataMatrix, we can include detailed information about each PCB, including serial number, production date or component batch data. This is a key advantage in industries that require full transparency and tracking, such as the automotive industry, where even the smallest errors can have serious consequences.

Benefits for various industries

Laser marking of PCBs is particularly important for industries that require precise quality management and component tracking. In automotive and aerospace, the ability to identify each PCB and its components used in an application can significantly speed up the process of detecting and eliminating defective components, which increases the safety and reliability of final products. Likewise in the medical industry, where accuracy and batch traceability of components are critical to patient safety. Upon request, we also mark enclosures to help meet specific product traceability requirements.

Summary

Laser marking is a forward-looking technology that significantly outperforms other marking methods in terms of durability, precision and operating costs. At PROPCB, we use this method to provide our customers with the best solution in terms of tracking each PCB and full transparency of production processes. Our laser marking is durable, precise and resistant to external factors, making it ideal for industries that require reliability and full control over product quality.

Feel free to contact us to learn more about our PCB laser marking services and see how we can help you with your project!