DISCOVER OUR RANGE OF PCB TYPES

At PROPCB, we offer a wide range of printed circuit boards designed to meet diverse needs, from simple single-sided constructions to advanced multilayer and specialized solutions. Thanks to advanced technologies and precise production processes, we ensure high quality and reliability, even in the most demanding applications.

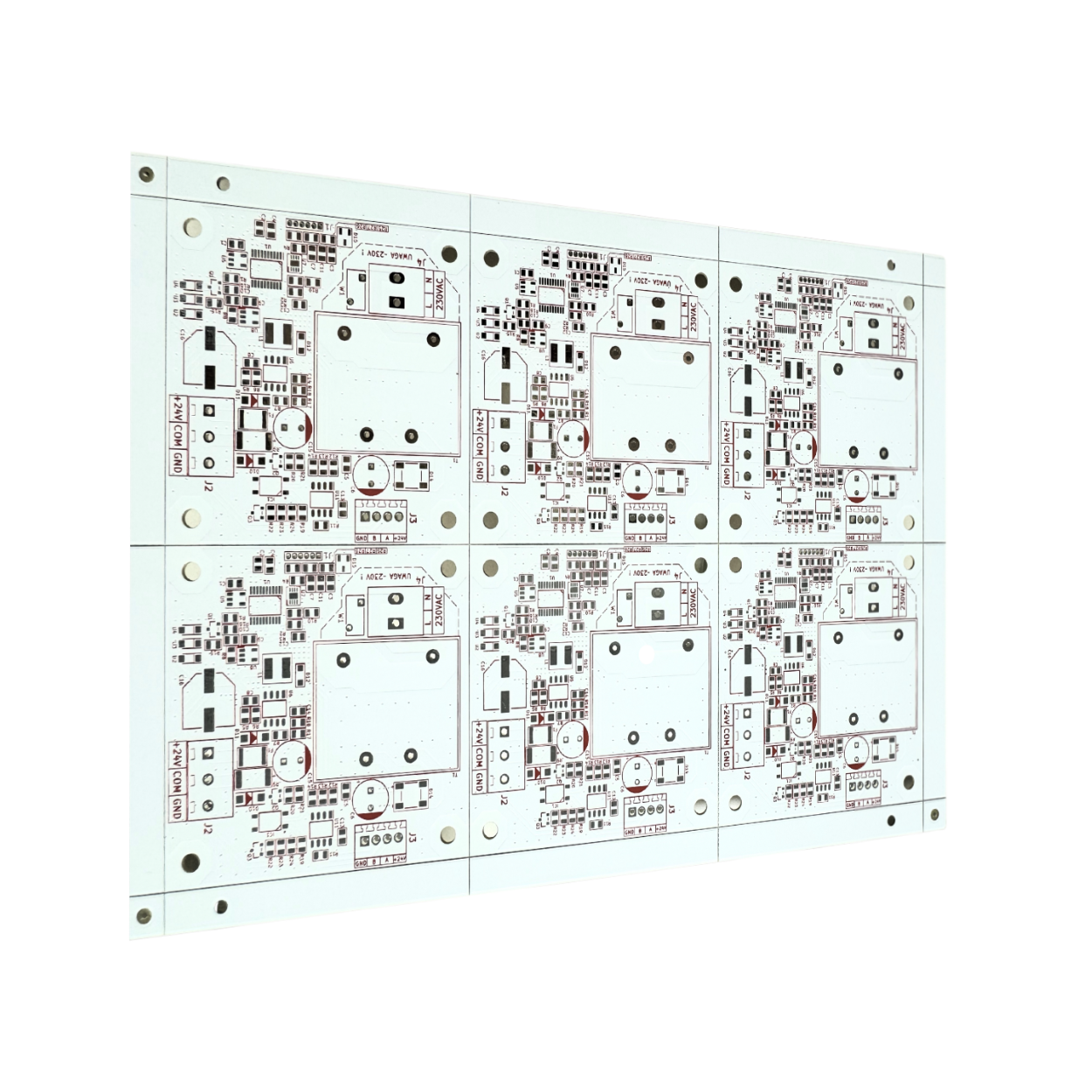

SINGLE-SIDED PCB

PCBs with all traces and components located only on one side. These are the simplest PCB constructions, used primarily in devices with low complexity, such as remote controls, calculators, and low-cost consumer electronics. Single-sided PCBs are easy to produce, resulting in lower costs, though their application is limited to projects with a small number of components and connections. In some cases, single-sided PCBs are used for heat dissipation in high-power applications.

RF AND MICROWAVE (MW) CIRCUITS

RF (Radio Frequency) and microwave PCBs are designed to operate at high frequencies, such as wireless communication, radar systems, and GPS. They require specialized materials like Rogers laminates, which offer excellent dielectric stability and low signal loss. Designing such boards requires precision to minimize interference and signal loss. RF circuits are widely used in telecommunications, radars, RF devices, and microwave systems, where signal stability and minimal disturbances are critical.

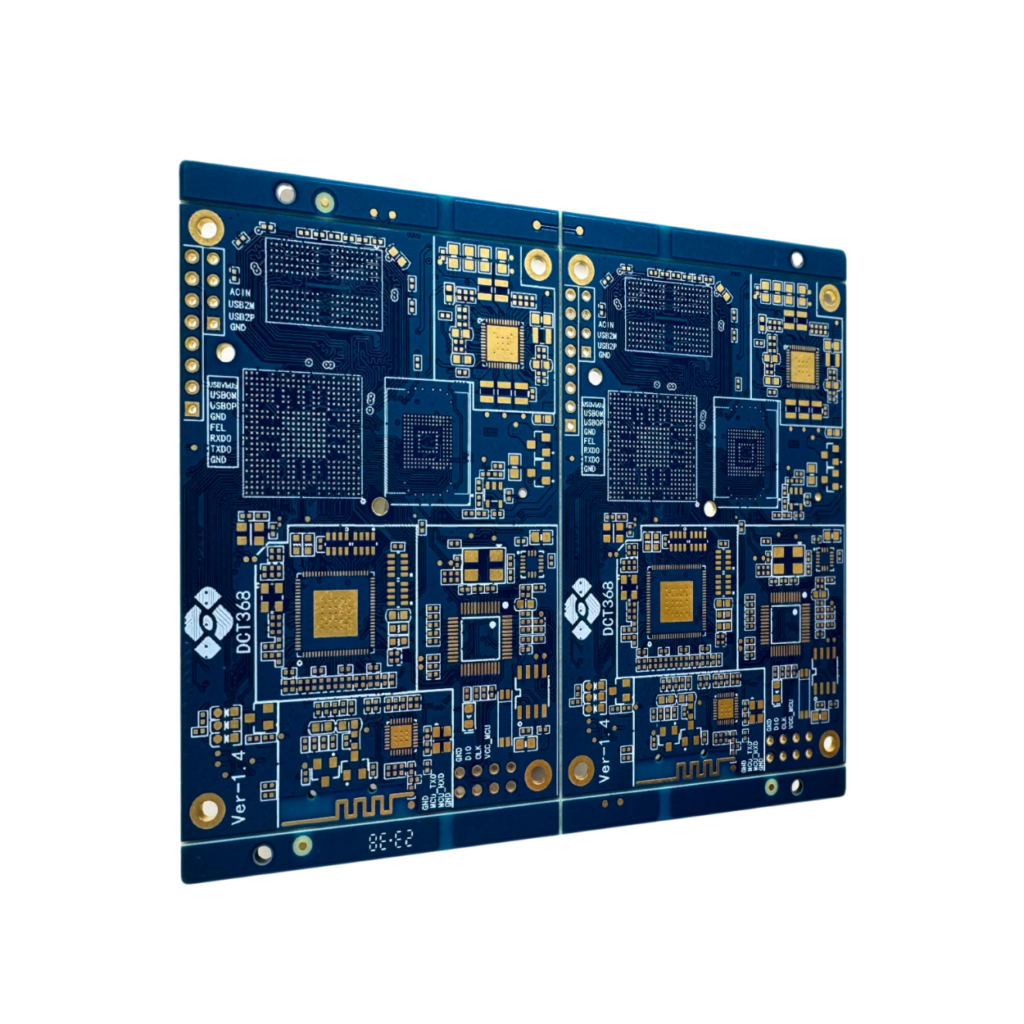

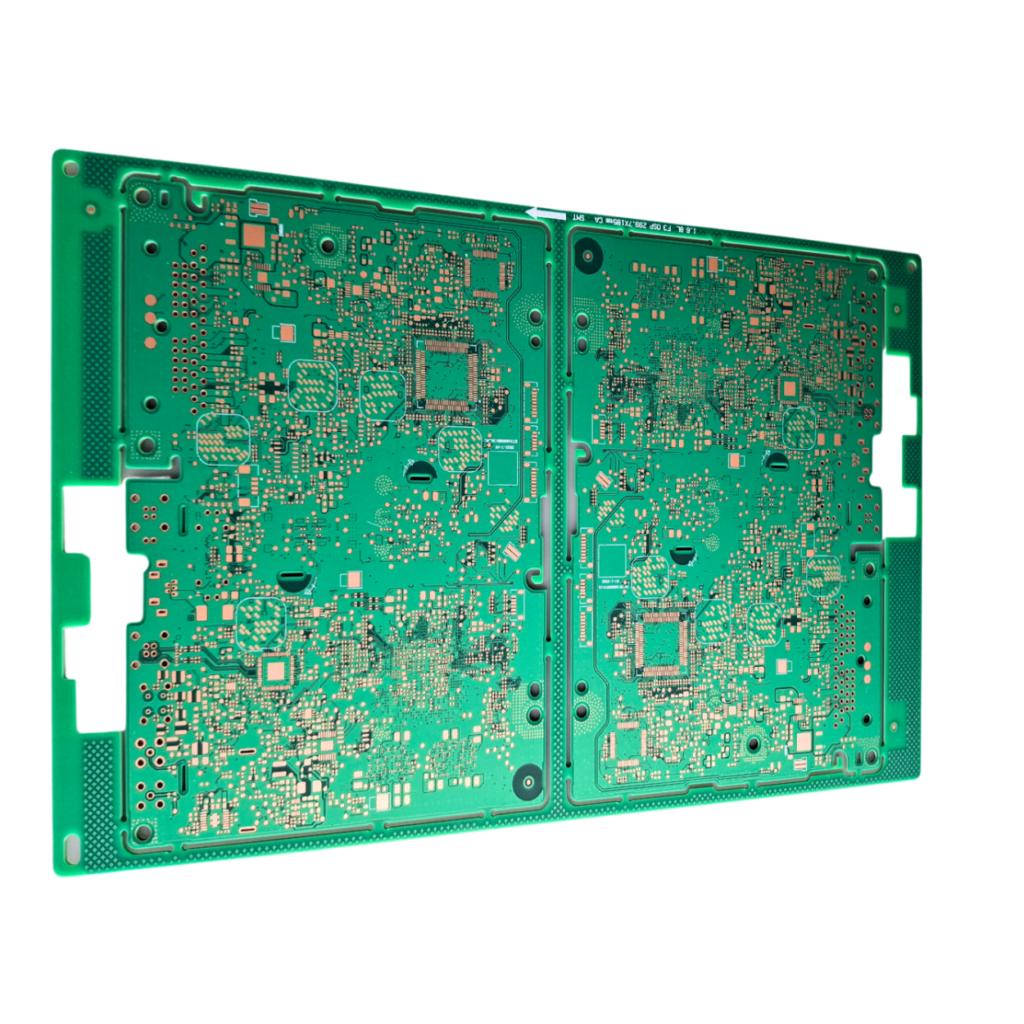

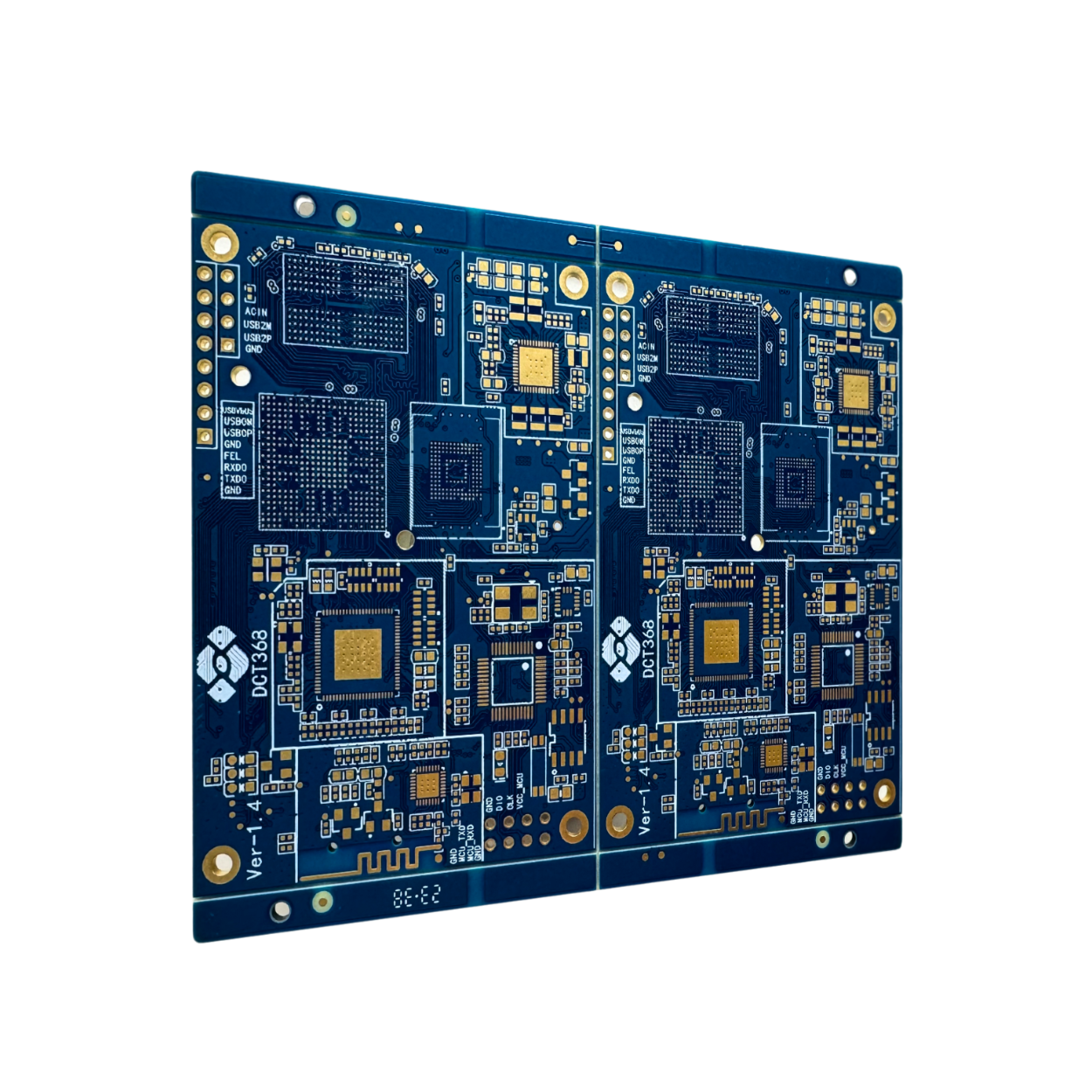

MULTILAYER PCB

These consist of multiple layers of copper and insulating material, laminated together to create a complex structure with more connections. The multilayer PCBs offered by PROPCB can have up to 40 layers, enabling the integration of very complex electronic systems. These solutions are essential in advanced electronics, such as servers, computers, telecommunications equipment, military, and aerospace systems, where maintaining signal integrity and reducing electromagnetic interference (EMI) is crucial. Internal layers can be dedicated to power or grounding, improving stability and reducing interference.

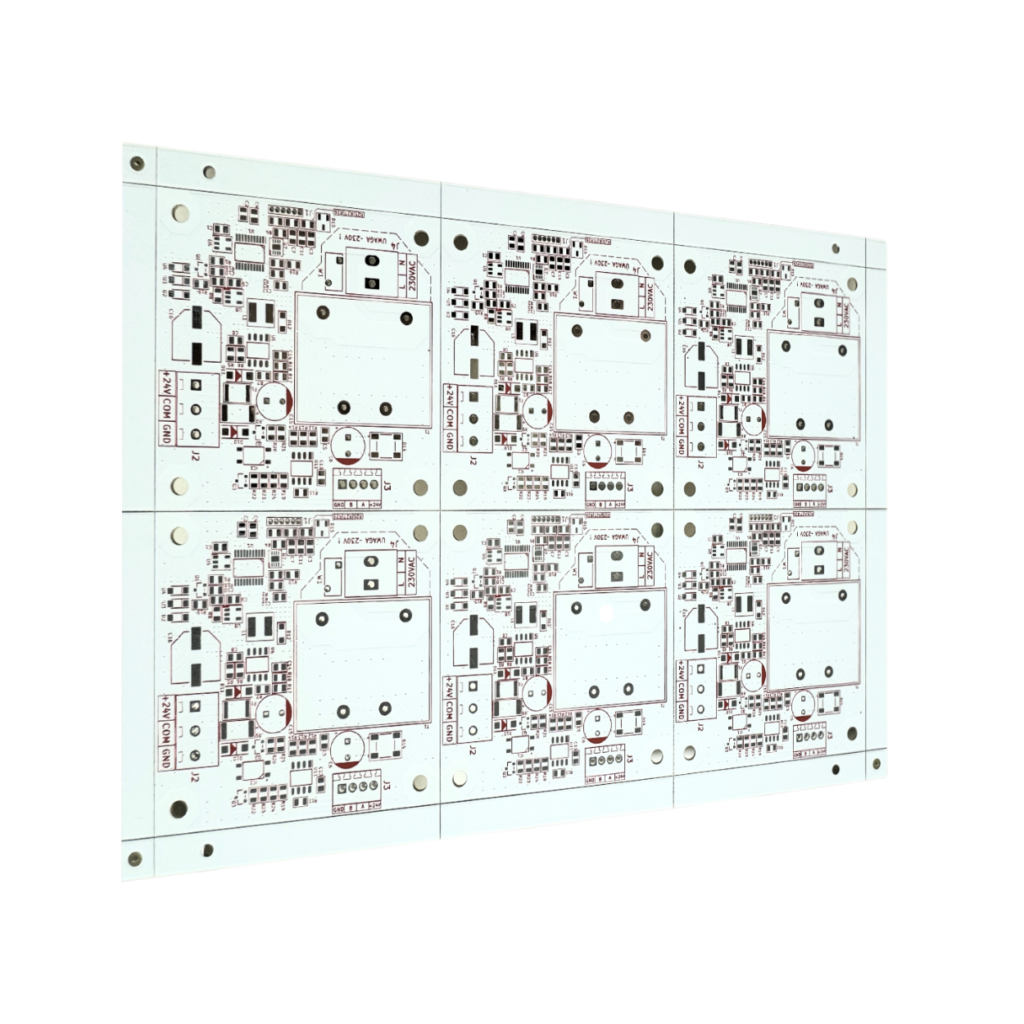

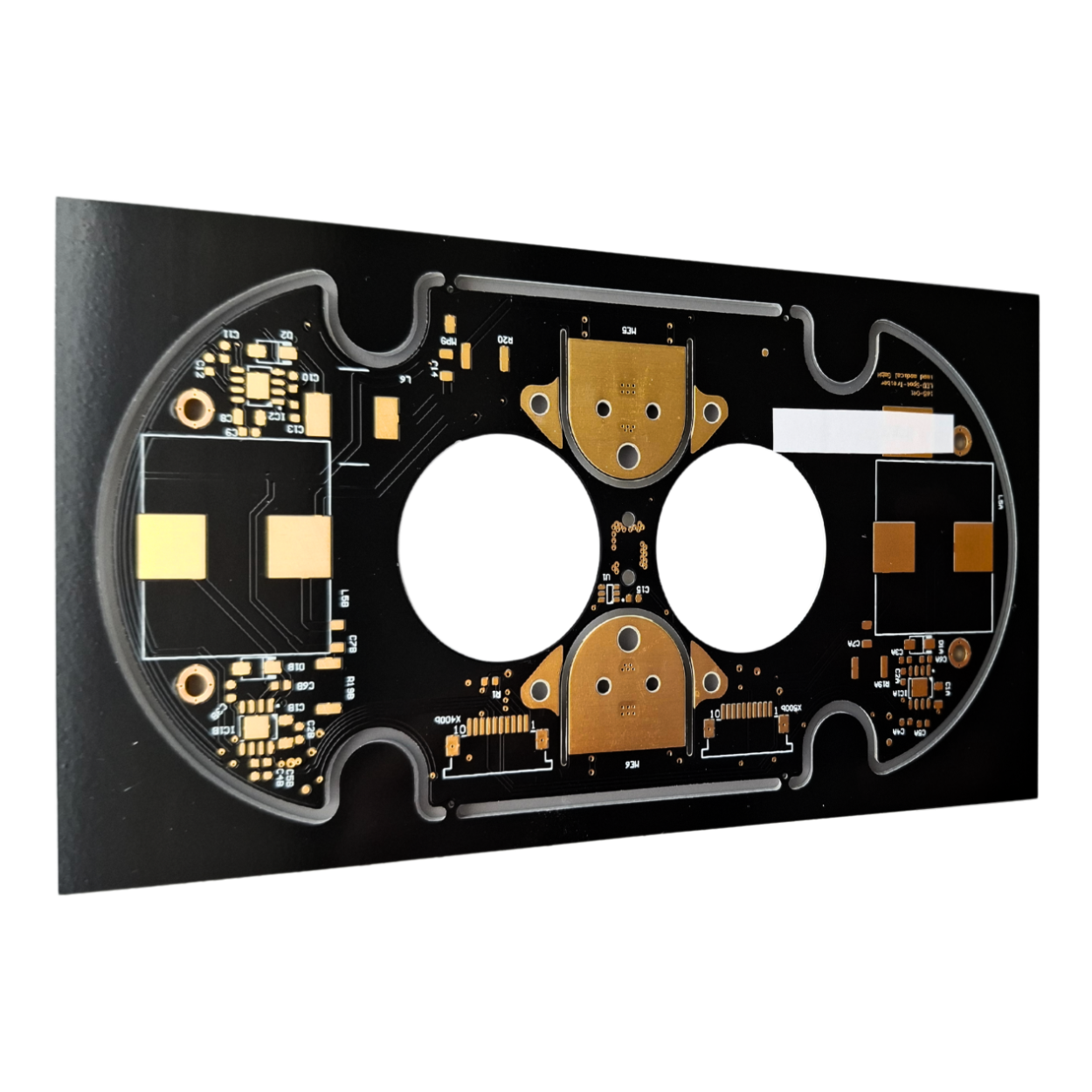

IMS PCBs – METAL CORE (ALUMINUM OR COPPER)

IMS (Insulated Metal Substrate) PCBs are specifically designed for applications where efficient heat dissipation is crucial. With a metal core – aluminum or copper – IMS boards are ideal for LED systems, power converters, automotive electronics, and all applications where high temperatures may affect component performance. The metal core acts as a heat sink, providing effective cooling and extending the device’s lifespan.

HDI – HIGH-DENSITY INTERCONNECT PCB

HDI (High-Density Interconnect) PCBs feature small vias, thin traces, and high connection density on a small area. HDI technology saves space and increases the number of components in compact devices like smartphones, tablets, medical equipment, and advanced portable electronics. A distinguishing feature of HDI PCBs is the use of special vias – microvias, blind vias, and buried vias – which allow better connection distribution and minimize signal disturbances in multilayer designs.

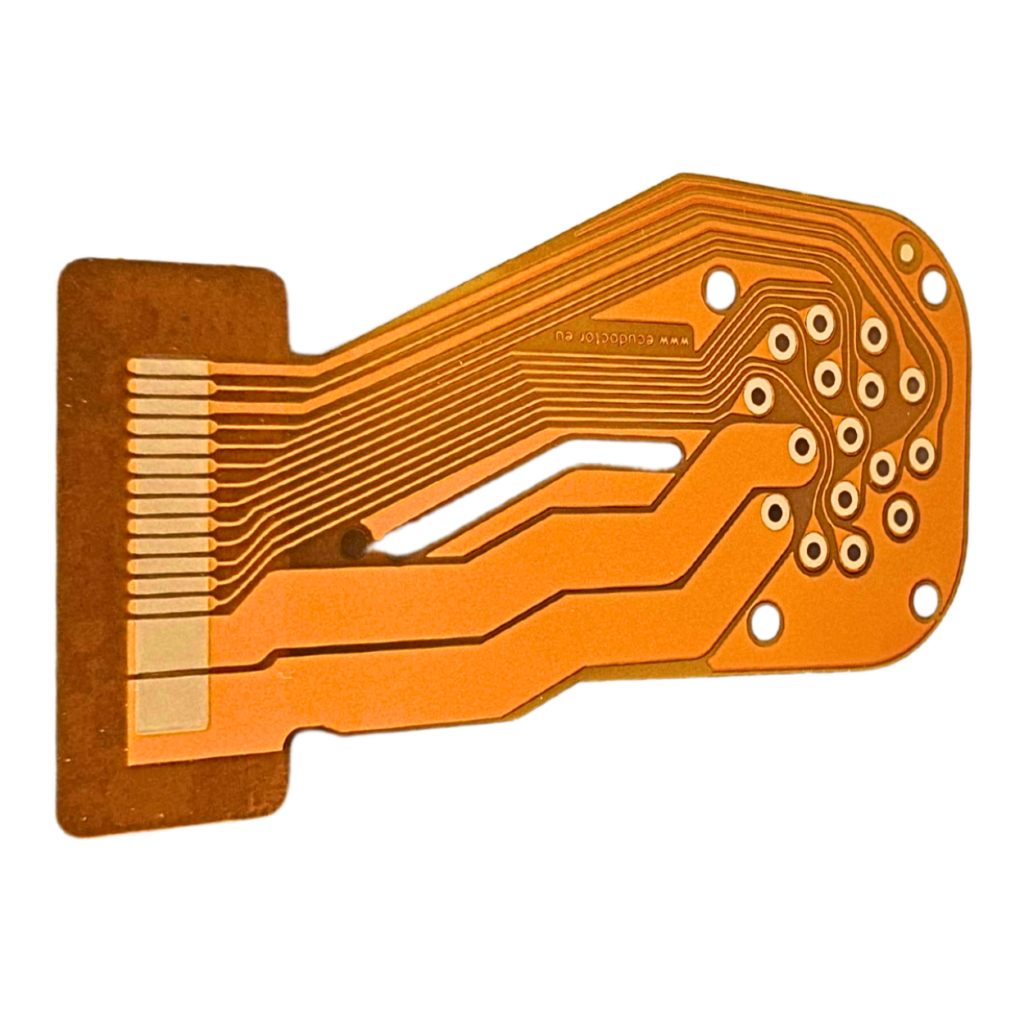

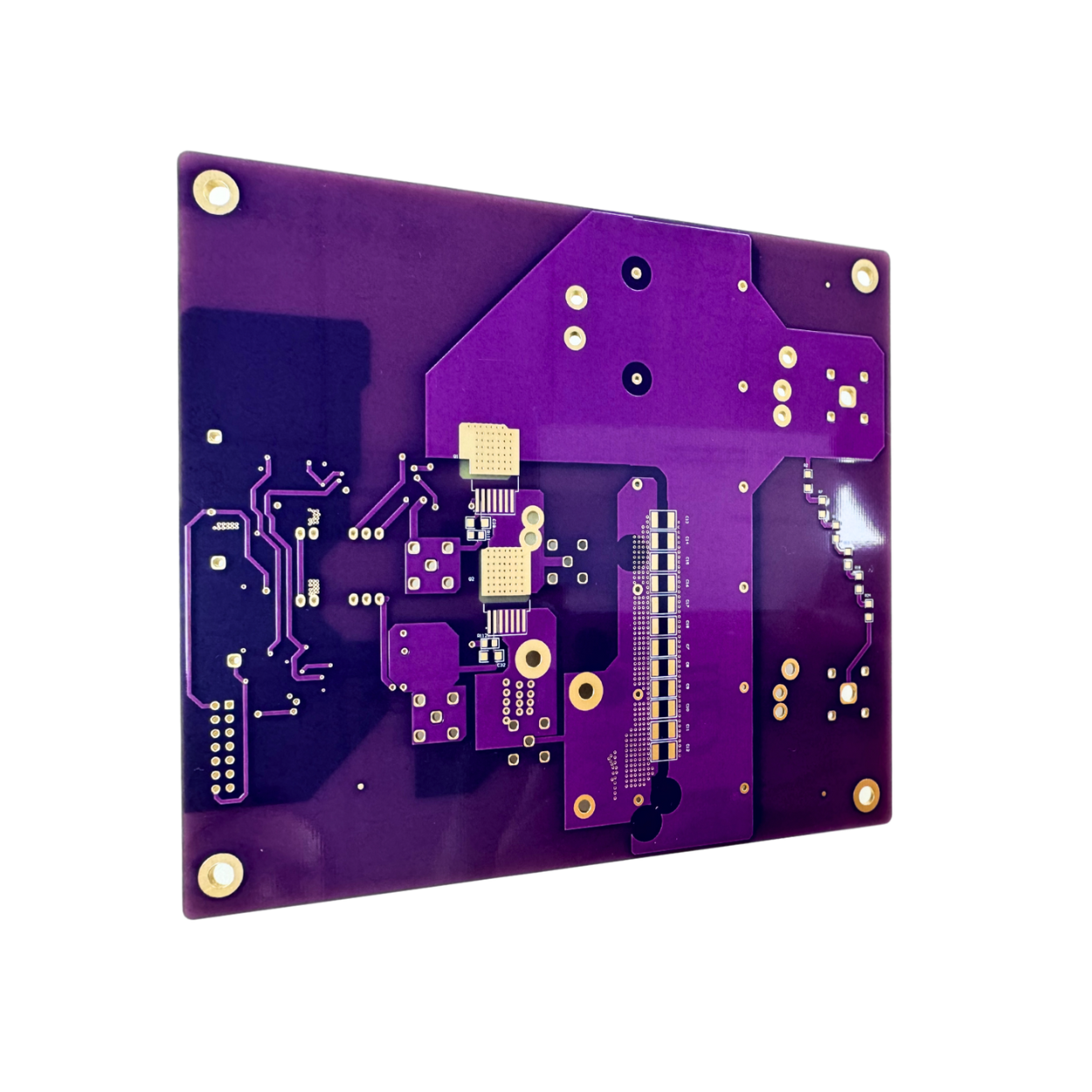

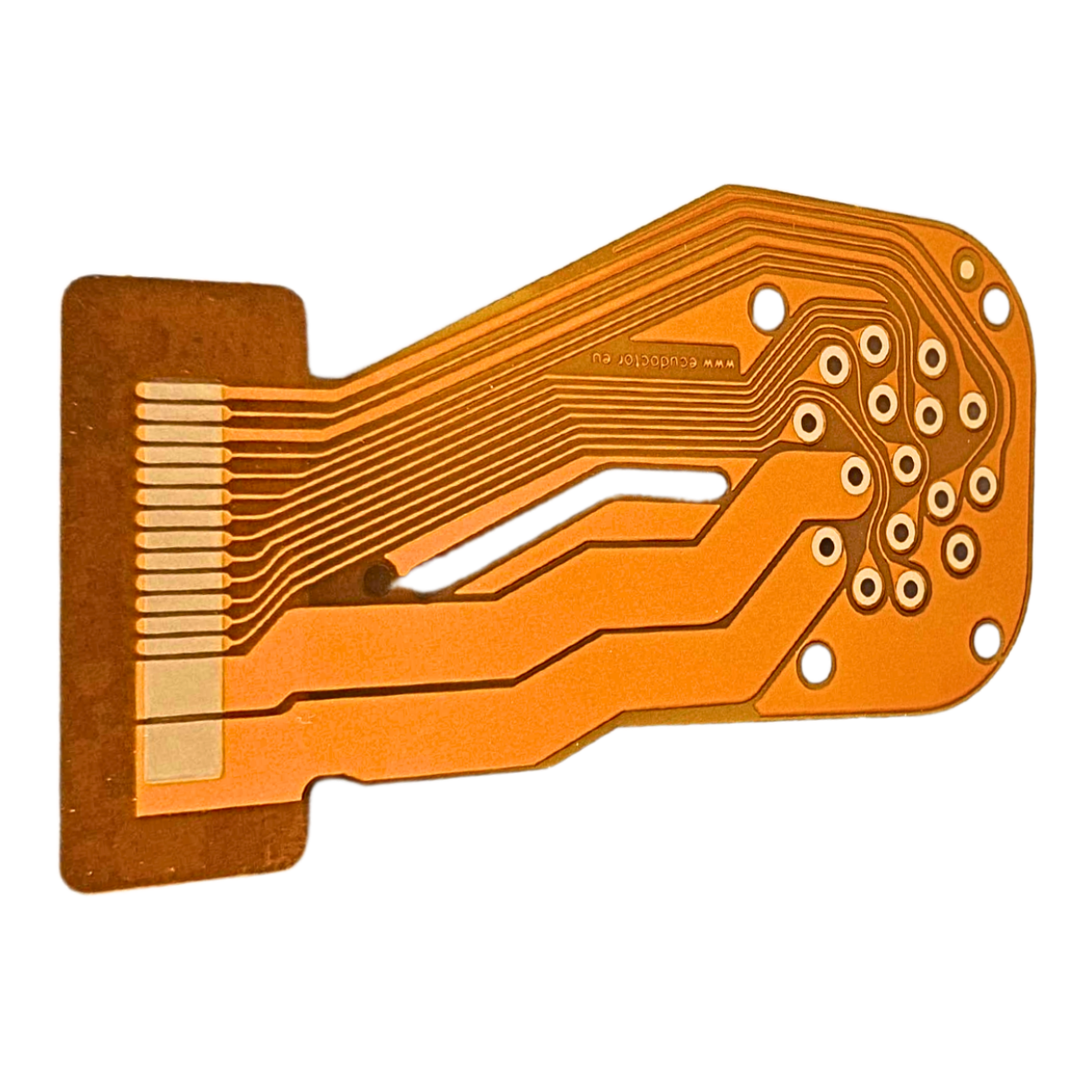

FLEXIBLE PCB

As the name suggests, flexible PCBs are made of bendable materials, enabling their installation in non-standard shapes or where bending the board without damage is required. These boards are used in devices requiring flexibility, such as wearable electronics, medical devices, aerospace equipment, and systems where weight reduction and space savings are essential. Materials used for flex PCB production provide excellent mechanical strength, electrical insulation, and resistance to high temperatures.

DOUBLE-SIDED PCB

Double-sided PCBs allow traces on both sides of the board, enabling the placement of components on both surfaces and increasing the number of connections. Using vias, it is possible to connect the top and bottom layers, providing more design possibilities. These boards are used in more complex devices, such as sensors, audio equipment, power supplies, and industrial electronics, where precise space and connection management are necessary.

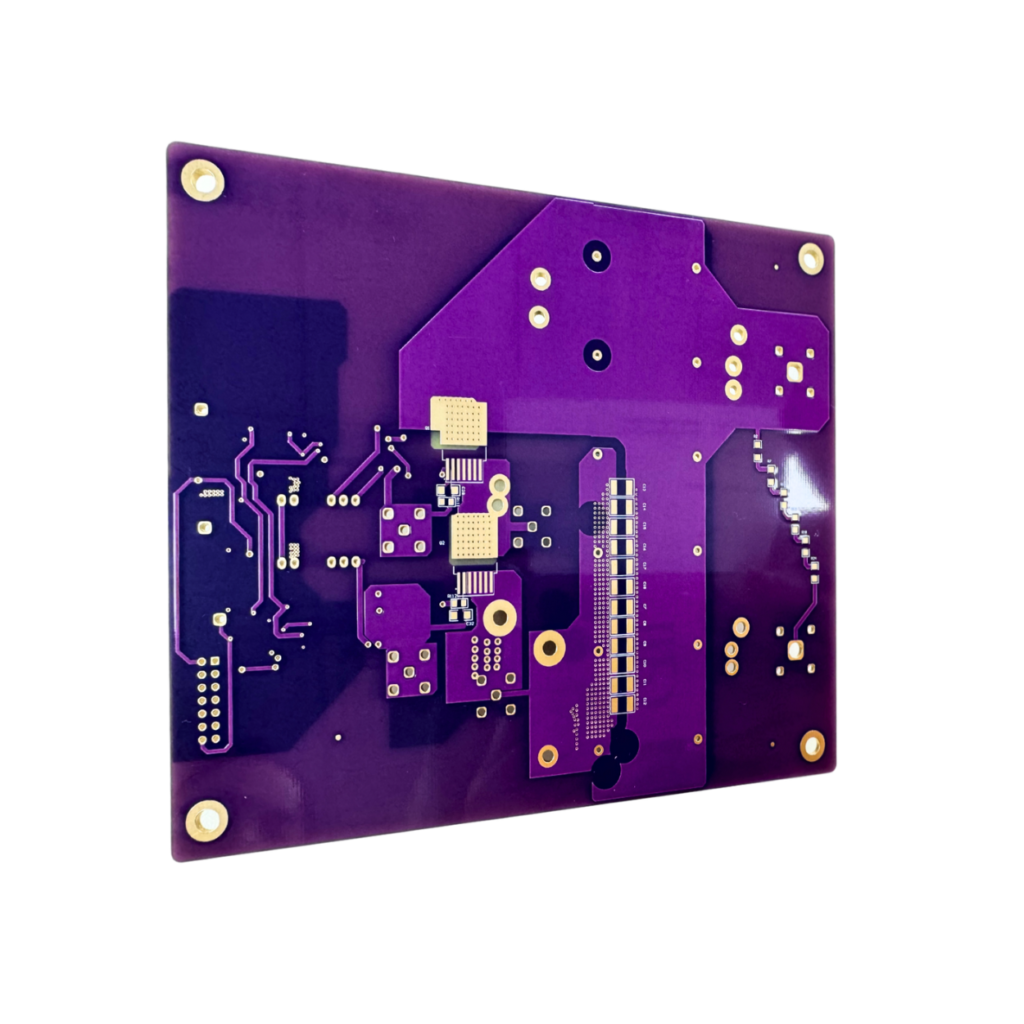

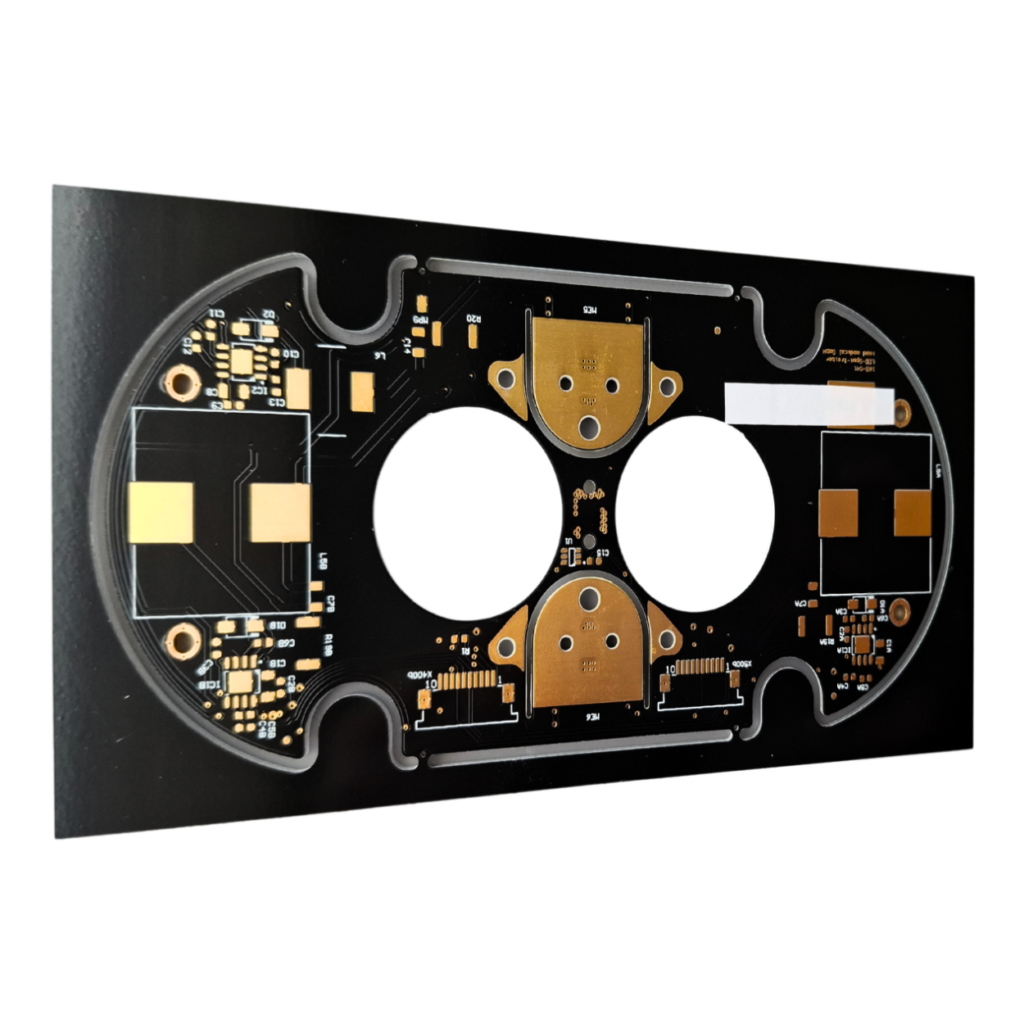

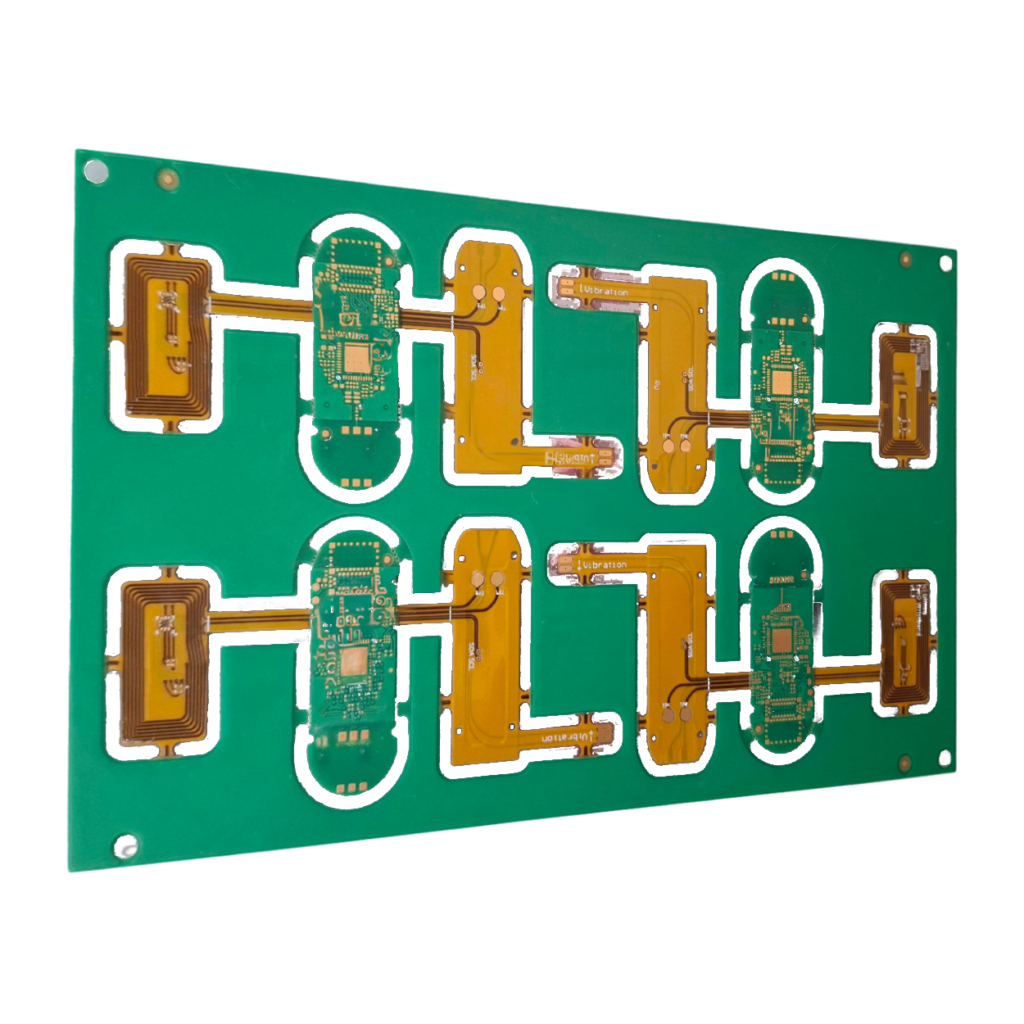

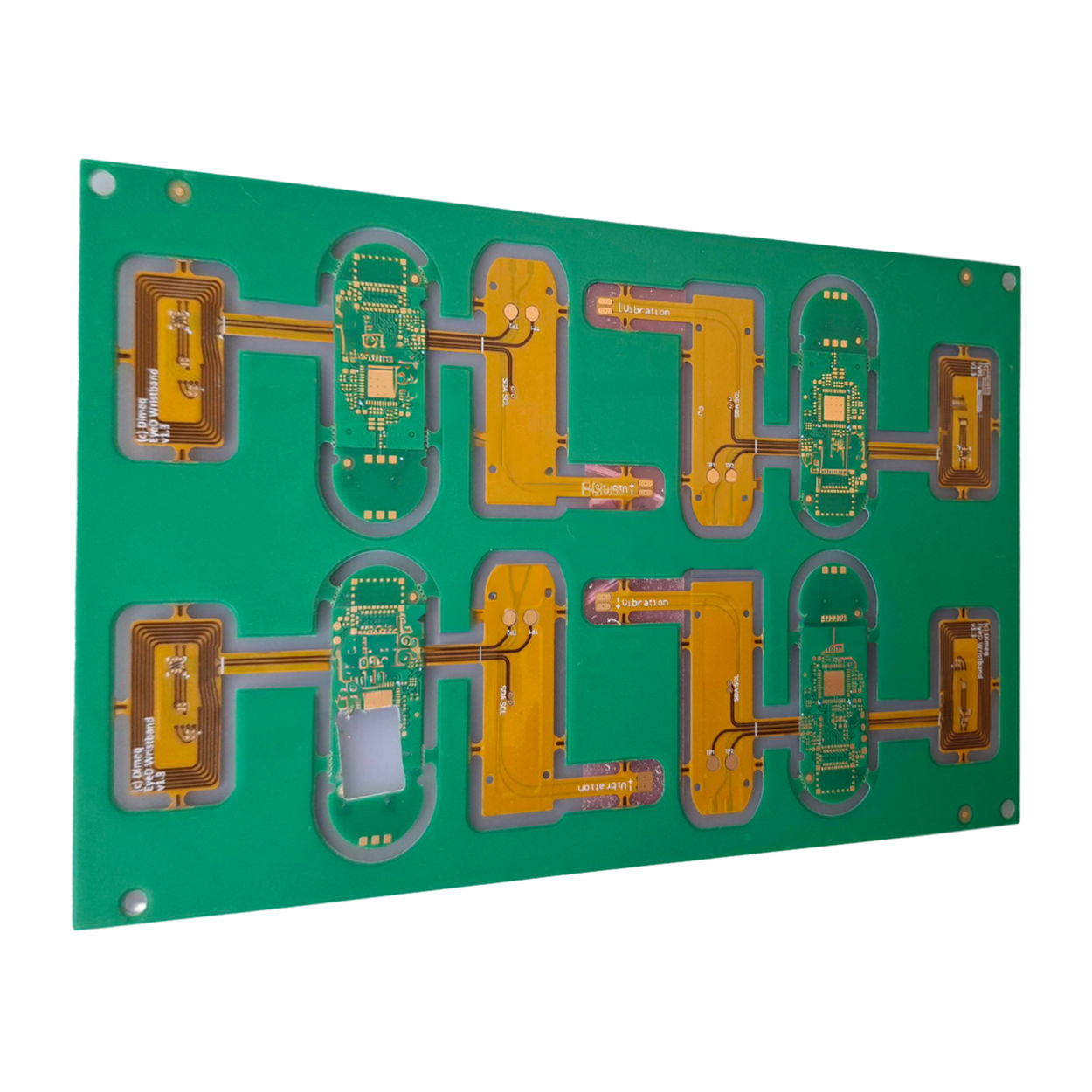

RIGID-FLEX PCB

Rigid-flex printed circuit boards combine the advantages of rigid and flexible boards in one construction, enabling the design of more complex systems, reducing the number of intermodule connections, and saving space. The use of rigid-flex PCBs also increases durability and reliability in some applications by eliminating connectors, which can be susceptible to damage and vibrations. These boards are widely used in military, aerospace, medical, and automotive applications, where reliability and durability are crucial.

LET US ASSIST YOU IN FINDING IDEAL SOLUTIONS TAILORED TO YOUR PROJECT

Do you have any questions about our PCB production technologies or need help selecting the right solution for your project? Our team of experts is at your service! Contact us for detailed information about our offer, to finalize technical specifications, and discuss prototype and series production possibilities. We are happy to advise and assist you with even the most demanding projects. Contact us today and find out how we can bring your idea to life!